A Guide To Buying Swivel Joints

If you have been a part of the engineering industry for some time, you will know what a swivel joint is. When any application needs pipe connections that have to be moveable, swivel joints come to the fore as far as importance is concerned. The slow rotational action ensures that the pipe system gets a lot of flexibility, which improves its functionality. But before you try to understand how to buy them, here are a few things to know about them.

Details about Swivel Joints

It is a flexible piping component that has been manufactured using precise machinery which gets installed between equipment, tools, hoses, and pipes. Their design is such that they allow one component of the equipment to move in relative to another.

While these are designed and manufactured mainly for industrial purposes, they can deal with extreme stress and tension. They are also able to function under extreme temperatures. They have a wide variety of applications they can be used for.

How to Buy Swivel Joints

For every industry that requires pneumatic and fluid pipe systems, swivel joints will be one of the most common things that come into play. There are a few things to keep in mind when buying them.

- Application: One of the first things to find out is what kind of application they are being bought for. This depends on the industry of the manufacturing unit. Common applications they are used for are chemical and the petrochemical industry, mining, metallurgy, power plants, the pharmaceutical industry, the refining industry, etc. The food and drinks industry also uses them. Choosing according to the particular application is necessary.

- Materials Used: Swivel Joints come in a variety of materials such as carbon steel, bronze, brass, aluminum, stainless steel, Hastelloy, etc. Depending on the temperatures they will be used at and the kind of physical stress they will be under, choose the material likewise.

- Specifications: Some of the common specifications that have to be studied are joint size, cold working pressure, operating pressure, torque drag, and the end connection. If you choose a longer-sized product, there will be reduced cases of abrasion and lesser vibration. Some products have specifications such as flanged, beveled, or threaded. Also, sometimes, products are designed to be in conformity with pressure vacuum vents, in places where reducing the evaporation of tank contents is necessary.

- Type of Fluid Being Used: A lot depends on the type of fluid that is being used. For instance, if the fluid can be contaminated, then a different type of product needs to be used rather than one that is being used for a hazardous fluid.

As long as the above points are kept in mind, the right products can be chosen.

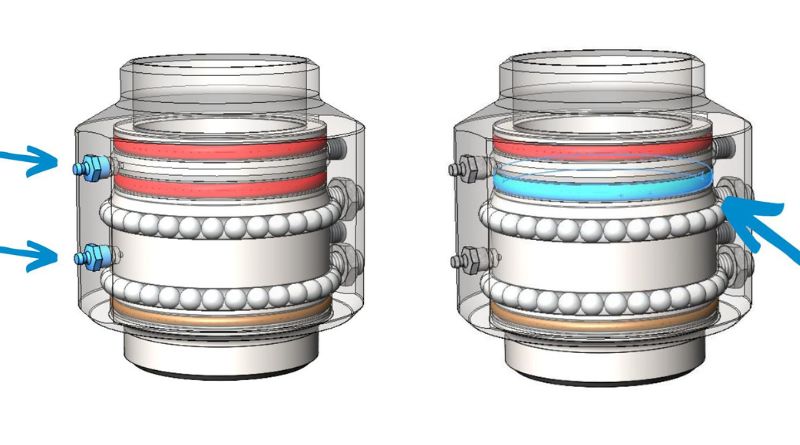

How Does a Swivel Joint Work?

Perhaps the most important thing to know about it is that it is made up of two components: the body and the sleeve. Ball-bearing races are used to lock both of them in place. These ball-bearing races are of incredible importance in the workings of the product themselves because it keeps the body and the sleeve properly aligned with each other. It allows the swivel to have a rotatory motion around the axis.

The ability of the two parts of the swivel to rotate also allows the piping system to rotate as well. It allows them to rotate independently and freely around the axis.

While some applications only require one rotation, many require multiple rotations and axes. This is possible when multiple swivels are installed and all of them have different orientations. A fluid conveyance system benefits a lot from such an independent range of movement and motion. To keep the swiveling function up, the ball-bearing races have to be lubricated properly.

A swivel needs to absorb the pressure of the joints for the application it is being used for. The higher its pressure rating, the more effectively it can operate. Also, give importance to the torque of the joints. If you need swivels for areas where the joints are going to come in contact with corrosive or hazardous substances, then make sure that you choose a product that is meant to handle that kind of physical stress and tension.

Top Characteristics of Swivel Joints

Now let’s look at the main characteristics of these products:

- Compact-sized engineering components

- Part of almost every engineering manufacturing industry

- Makes easy lubrication possible

- Bearings that last long

- The bearing chamber is protected which maintains the mechanism’s strength

- They are sustainable, safe, and rigid

- They make tight sealing possible

Reasons Why They Are a Must in Every Industry

It is natural to wonder what makes them a must in almost every industry you can think of.

- Universal Usage: Valves and pipes are important aspects of almost any type of industry. However, the problem with stationery valves and pipes is that they are next to impossible for the distribution of fluids. That is exactly where these products come to use. These make it possible for rotation to happen without any supporting structure. They are used across industrial settings and this makes them a must in most industries.

- Highly Cost-Effective: A big reason why they are so useful is that they allow factories to be more cost-effective. With them, less of hoses are required and this can bring down production costs by a good margin. It keeps costs low.

- Absorbs Shock: Swivel joints have been designed in a way so that they absorb shock when the system pressure changes. This is great because it means that damage to components can be prevented and the need for repairs can be avoided.

When choosing swivel joints, keep in mind what they are being used for and what their features are. There are top companies available that will even provide customised swivel products.